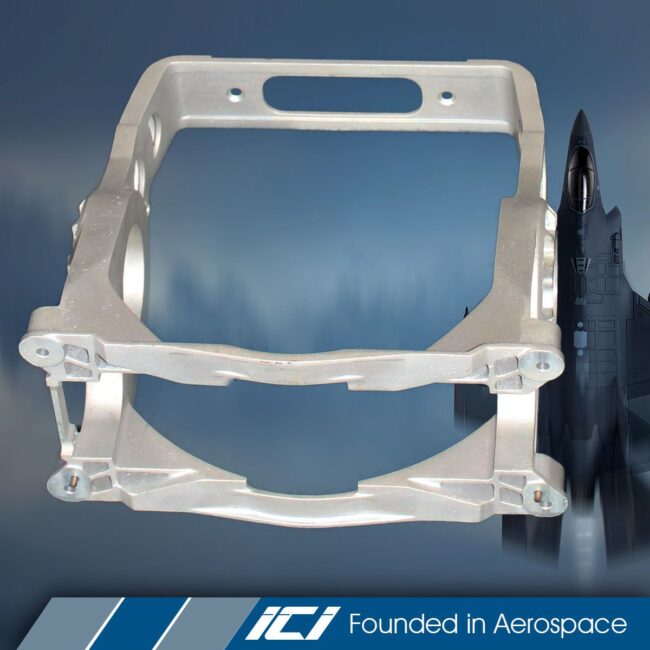

Metal Casting Solutions for Aerospace and Aviation

Metal casting plays a vital role in the aerospace and aviation industries, enabling the production of advanced components built to perform under extreme conditions. This process ensures high-performance parts that can withstand the severe temperature fluctuations commonly experienced in aerospace applications. Integra-Cast, Inc. — a Spartan Aerospace Group company — is a trusted leader in…