Understanding Common Casting Defects

Ensuring Precision in Every Component

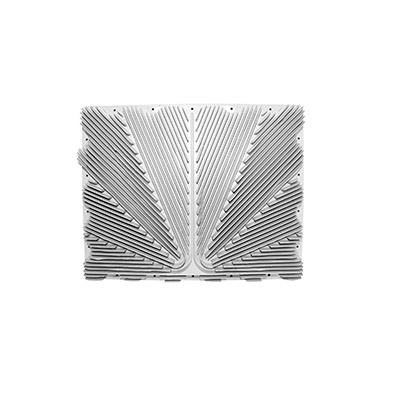

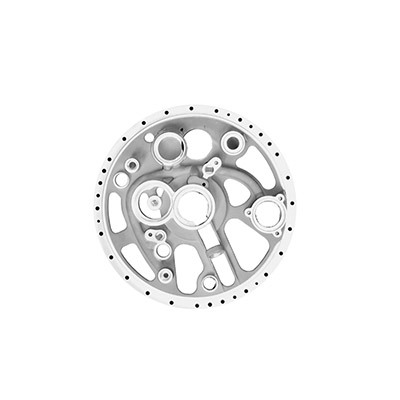

In the world of precision aluminum casting, defects can significantly impact product quality, structural integrity, and manufacturing costs. At Integra-Cast, Inc. (ICI), with over three decades of experience delivering aerospace-grade aluminum components, understanding and preventing casting defects remains central to our commitment to excellence. Whether producing complex geometries for aerospace applications or precision components for medical instrumentation, recognizing potential defects and their remedies ensures the highest quality standards our customers expect.

Primary Categories of Casting Defects

Casting defects typically fall into five main categories: gas porosity, shrinkage defects, mold material defects, pouring metal defects, and metallurgical defects. Each category presents unique challenges in the investment casting process that ICI specializes in, particularly when working with aluminum alloys for aerospace applications.

Gas Porosity: The Hidden Challenge

Gas porosity occurs when pockets form due to air or gas trapped in the metal during solidification. In aluminum castings, hydrogen is the primary gas that dissolves in significant quantities, potentially resulting in hydrogen gas porosity. These defects manifest as rounded cavities or holes, ranging from tiny pinholes (approximately 2mm) to larger blowholes visible on the casting surface.

For aerospace components where ICI specializes, controlling gas porosity proves critical. Our state-of-the-art foundry employs careful melt preparation techniques and optimized pouring temperatures to minimize gas entrapment. Proper venting of die cavities and controlling injection pressure during the investment casting process significantly reduces porosity formation.

Shrinkage Defects: Managing Solidification

Shrinkage defects occur when standard feed metal cannot compensate for volume reduction as the metal solidifies. These defects present two distinct forms:

Open shrinkage defects appear on the surface as pipes (holes burrowing into the casting) or caved surfaces (shallow cavities across the surface). Closed shrinkage defects, also called shrinkage porosity, form within the casting at hot spots where isolated pools of liquid metal solidify unevenly.

ICI’s investment casting process, capable of producing aluminum walls as thin as 0.75mm, requires precise temperature control and strategic gating design. Simulation analysis during the design phase helps identify potential shrinkage areas, allowing our engineers to optimize runner and gate geometries before production begins.

Pouring Defects: Cold Shuts and Misruns

Misruns occur when liquid metal fails to completely fill the mold cavity, leaving unfilled portions, while cold shuts happen when two metal flow fronts fail to fuse properly, creating weak spots. Both defects typically result from insufficient metal fluidity or inadequate pouring temperature.

Our precision machining facility and in-house CNC capabilities allow ICI to maintain optimal pouring temperatures and flow rates, particularly crucial when creating complex aerospace components like engine parts, wing brackets, and fuselage frames. Proper gating system design ensures complete mold filling, preventing these critical defects.

Inclusions: Maintaining Purity Standards

Inclusions refer to foreign particles such as sand or oxides embedded in the casting during pouring, which can weaken specific areas and reduce overall quality. For aerospace and medical applications where ICI operates, maintaining material purity proves essential.

Prevention Through Advanced Technology

Prevention strategies at ICI incorporate multiple approaches:

Process Control: Optimizing structural design ensures even wall thickness, while improved venting performance and appropriate pressure-holding times minimize defect formation.

Quality Monitoring: Our NADCAP-certified processes include comprehensive testing protocols. Visual inspection identifies surface irregularities, while radiographic testing examines internal structures for hidden defects.

Simulation Software: 3D simulation software allows designers to refine casting geometry and rigging design parameters before production, substantially reducing development time and minimizing defects.

Temperature Management: Maintaining precise temperature control throughout the casting process prevents premature solidification that causes misruns and cold shuts while reducing shrinkage-related defects.

Continuous Improvement for Aerospace Excellence

As the largest aerospace solid mold investment casting foundry in the United States, ICI’s commitment to defect prevention drives our continuous improvement initiatives. Our certification programs and industry partnerships ensure our team stays current with emerging technologies and best practices in defect prevention.

Understanding casting defects and their prevention remains fundamental to producing ready-for-assembly precision aluminum components. Through advanced technology, rigorous quality control, and decades of expertise, ICI continues delivering components that meet the demanding requirements of aerospace, electronics, medical, and instrumentation industries.